Skip to content

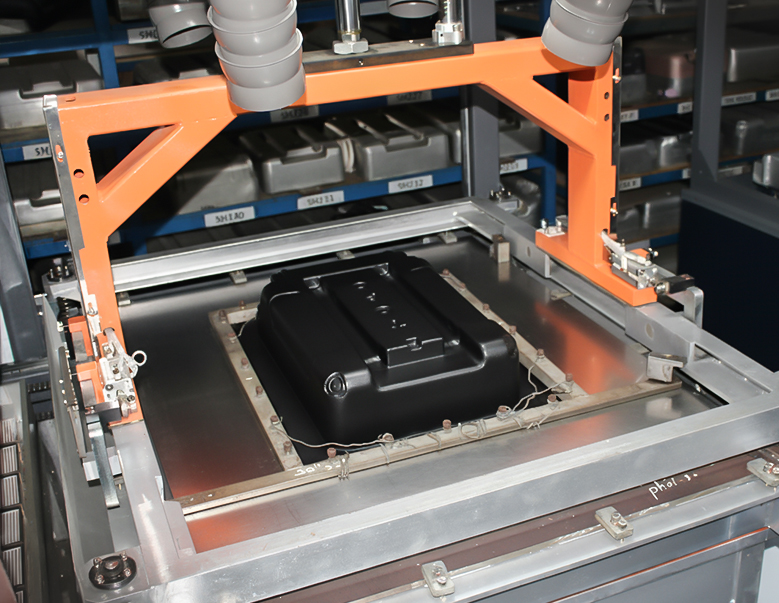

VACUUM MOLDING MACHINE

Process flow

- The molding machine must be pre-heated to the required temperature before production begins.

- Adjust the temperature of the machine on the parts that are out of shape.

- The mold must be cooled down after each case cycle before proceeding to the next one. This ensures the case maintains its final, accurate shape upon removal.

- The complexity of the case design determines the number and size of the mold holes (vents). Deeper designs require larger vent holes to ensure complete air extraction during vacuum forming.